Our Expertise

Experienced &

Innovative in Flare and Special Lifting Services

Flare Tip Replacement

Flare Tip Replacement for On- and Offshore

Suprotech brings unparalleled expertise in flare tip replacements, both on- and offshore, covering any kind of onshore flares to offshore flare booms on platforms and FPSOs.

Our experts can access any location within any environment around the globe and recommend the most effective flare tip replacement method from our extensive portfolio, which includes: traditional cranes, Ultralight Single Pole (USPS) or Ultralight Double Pole System (UDPS), Flare Tip Handling System (FTHS), davit system, or de-mountable flare systems with winches.

Suprotech’s state of-the-art Flare Tip Handling Systems

Our FTHS features a modular design, making it suitable for most on- and offshore flare structures, including flare booms and FPSOs. No additional cranes or helicopters are required, as all loads can be lifted by winches and our bespoke handling systems. The FTHS can be deployed on existing assets or serve as an effective alternative to a retractable davit system.

Guy Wire Service

Inspection

and Maintenance

Suprotech has developed a safe and efficient way to professionally inspect, evaluate and service all guy wires.

With our Motor Operated Crawler (MOC) and MRT technology, guy wires can be inspected online, while keeping all personnel safely on the ground. The inspection is done before a shutdown so when necessary, new guy wires can be supplied and replaced during a shutdown.

Existing guy wires can be cleaned and lubricated using our innovative lubrication technology. Flare alignment can then be surveyed and adjusted, taking guy wire tension values into account.

Inspection of bridge strands often necessitates closing the bridge. Suprotech’s remote-controlled MOC removes this requirement, allowing engineers to work safely from the ground, without disrupting traffic. All inspections are carried out using ISO 4309:2017-compliant NDT equipment.

Guy Wire Services

Cleaning and lubricating

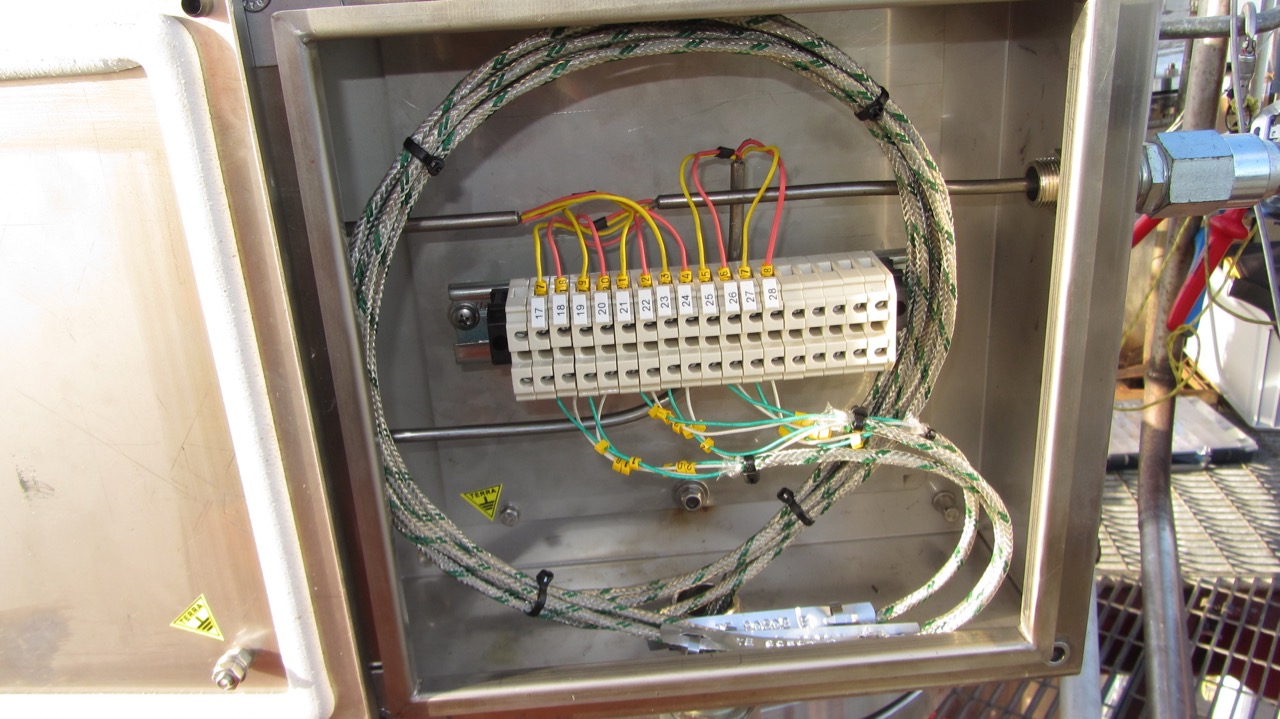

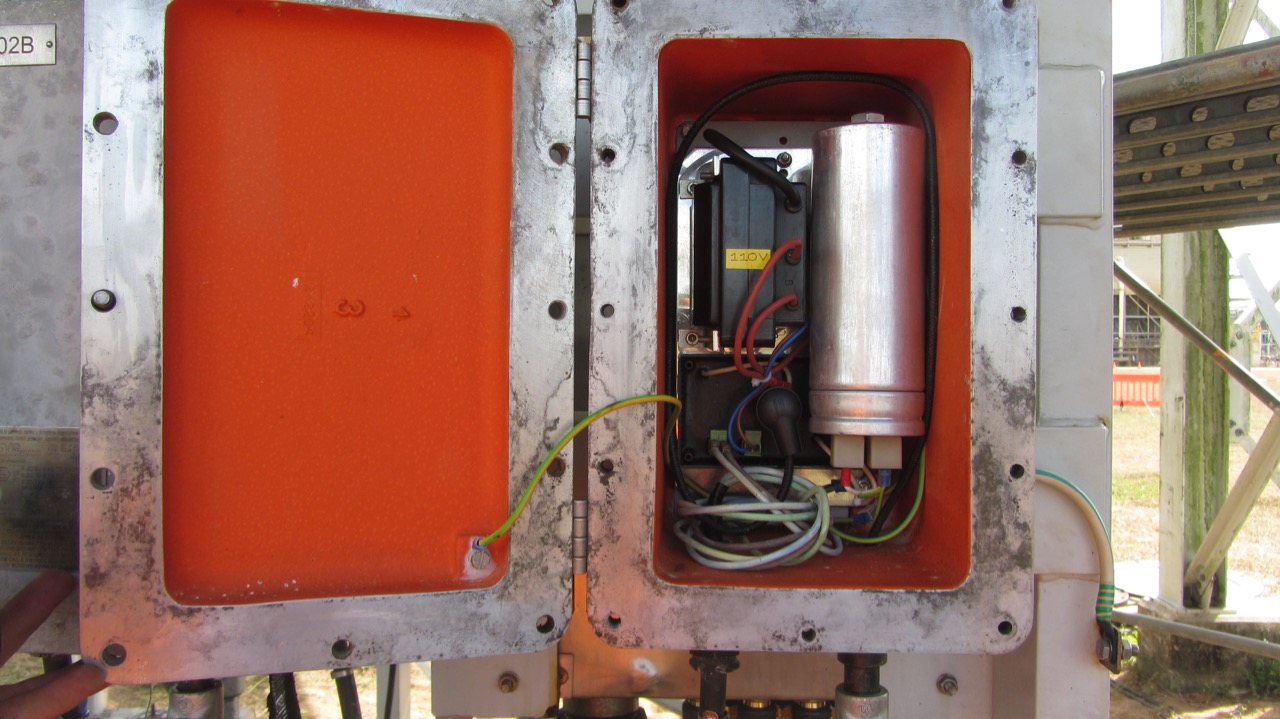

E&I Installations, Upgrades and Replacements

Highly Skilled E&I Experts using state-of-the-art Equipment

We provide installation and supply of E&I equipment, including High Energy Ignitors (HEI), Thermocouple Cables (TC), Aircraft Warning Lights (AWL), Flame Front Generators (FFG), and UV cameras.

Hydro Shield

Protective Hydro Shield System with Unlimited Coverage

We provide custom design, construction, installation, and operation of our Hydro Shield solution with standalone pumps. Suitable for all flare types, the Hydro Shield offers effective radiation protection for personnel working on live flares, helping to prevent costly shutdowns.

Only Lloyd’s-certified, high-volume, heat-suppressing nozzles are used, capable of reducing radiated heat flux from up to 40kW/m2 to below 3kW/m2. This ensures personnel safety and full compliance with HSE requirements and API 521 standards.

Flare Construction

Specialists in Flare System Construction

We construct all types of flare systems, including self-supported, guy wire, demountable, derrick, and ground flares.

We offer a complete installation service including the erection of riser and derrick structures, utilities, E&I, guy wire systems, flare tips, and commissioning as required.

Flare Construction

Complete Installation Service

Rope Access Services

Rope Access for On- and Offshore Projects

Suprotech’s rope access technicians are IRATA-certified, and we complement their expertise with portable, movable platforms to ensure the most cost-effective access solutions for our clients.

Suprotech’s rope access team can be deployed at any project location both on- and offshore.

Cleaning & Coating

Innovative in Online Pilot Line Cleaning

Suprotech performs internal riser and header line cleaning without the need for confined space entry. We can tackle blocked pilot lines whether on- or offline.

We provide blasting and coating of derrick structures and flare stacks without the need for costly cranes. Our experienced IRATA-certified technicians can safely access even the most hard-to-reach areas.